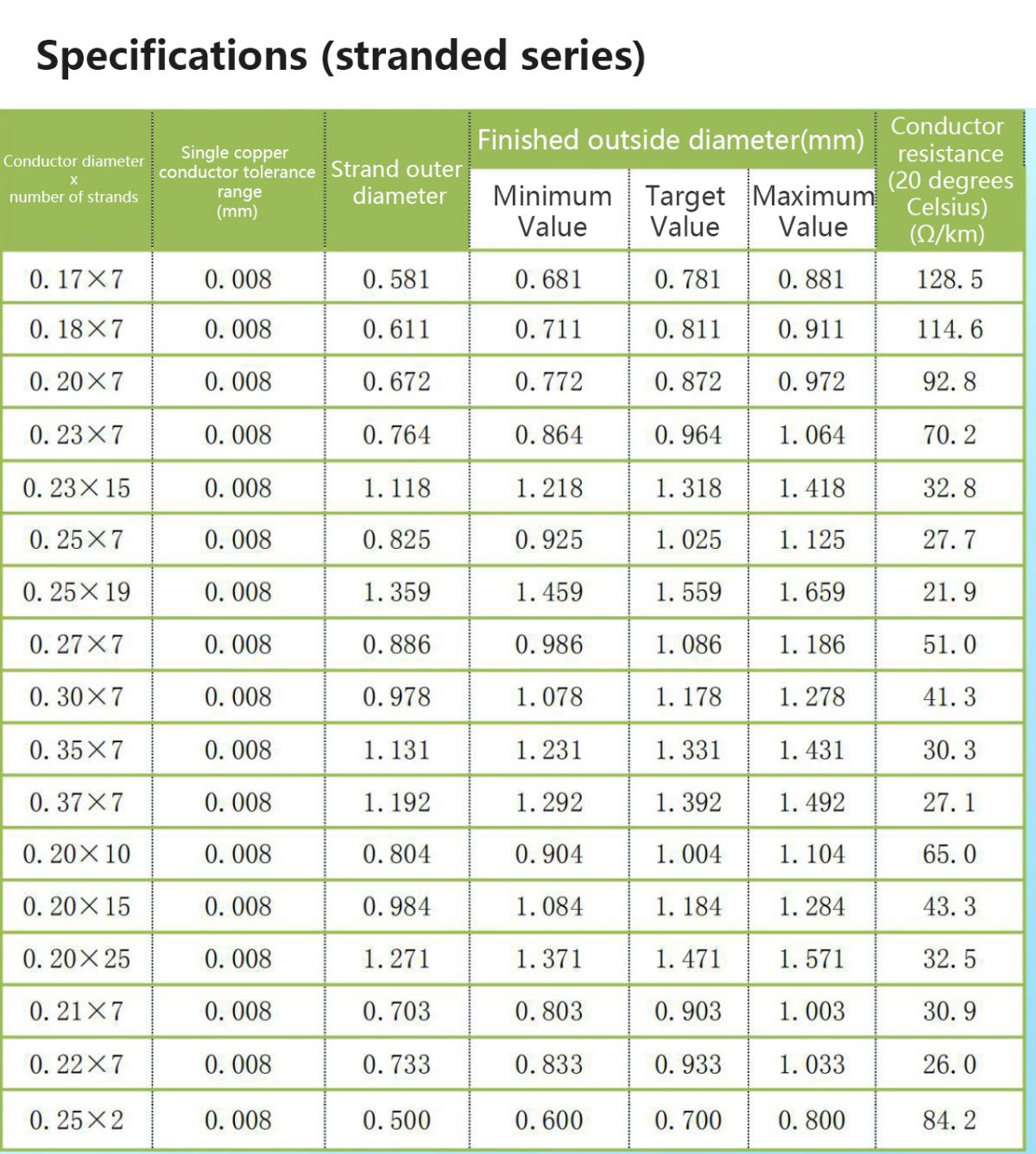

The first step is laying out;the second step is decontamination;and the third step is preheating. The fourth step is the first extrusion;the fifth step is the first cooling;the sixth step is the infrared diameter detector to check whether the wire diameter is qualified, the seventh step is the second extrusion;the eighth step is the second cooling;the sixth step Nine steps of infrared diameter detector inspection, tenth step of nylon outer layer extrusion molding, eleventh step of third cooling; twelfth step of infrared diameter final inspection;thirteenth step of drawing wire;fourteenth step of winding .This product is mainly used in: high-power power supply, industrial power supply, military equipment, medical equipment and other scenarios.The product company can manufacture the following specifications: 0.05mm~1.0mm (single core wire) 0.05mm*7P~0.05mm*3000P (multi-strand wire)1. It has excellent corrosion resistance, almost insoluble in any organic solvent, and can resist oil, strong acid, strong alkali, strong oxidant, etc. 2. It has excellent electrical insulation performance, high voltage resistance, low loss at high frequency, and no moisture absorption. 3. It has excellent anti-aging performance and long service life. 4. Our company's extrusion equipment is connected to the online monitoring system, and the wire quality is monitored in real time. 5. The tolerance accuracy of a single wire rod can be controlled at ±0.01mm (China industry standard tolerance ±0.02mm).The specific price is set according to the daily international copper and aluminum prices, if necessary, please contact us.

The first step is laying out;the second step is decontamination;and the third step is preheating. The fourth step is the first extrusion;the fifth step is the first cooling;the sixth step is the infrared diameter detector to check whether the wire diameter is qualified, the seventh step is the second extrusion;the eighth step is the second cooling;the sixth step Nine steps of infrared diameter detector inspection, tenth step of nylon outer layer extrusion molding, eleventh step of third cooling; twelfth step of infrared diameter final inspection;thirteenth step of drawing wire;fourteenth step of winding .This product is mainly used in: high-power power supply, industrial power supply, military equipment, medical equipment and other scenarios.The product company can manufacture the following specifications: 0.05mm~1.0mm (single core wire) 0.05mm*7P~0.05mm*3000P (multi-strand wire)1. It has excellent corrosion resistance, almost insoluble in any organic solvent, and can resist oil, strong acid, strong alkali, strong oxidant, etc. 2. It has excellent electrical insulation performance, high voltage resistance, low loss at high frequency, and no moisture absorption. 3. It has excellent anti-aging performance and long service life. 4. Our company's extrusion equipment is connected to the online monitoring system, and the wire quality is monitored in real time. 5. The tolerance accuracy of a single wire rod can be controlled at ±0.01mm (China industry standard tolerance ±0.02mm).The specific price is set according to the daily international copper and aluminum prices, if necessary, please contact us.