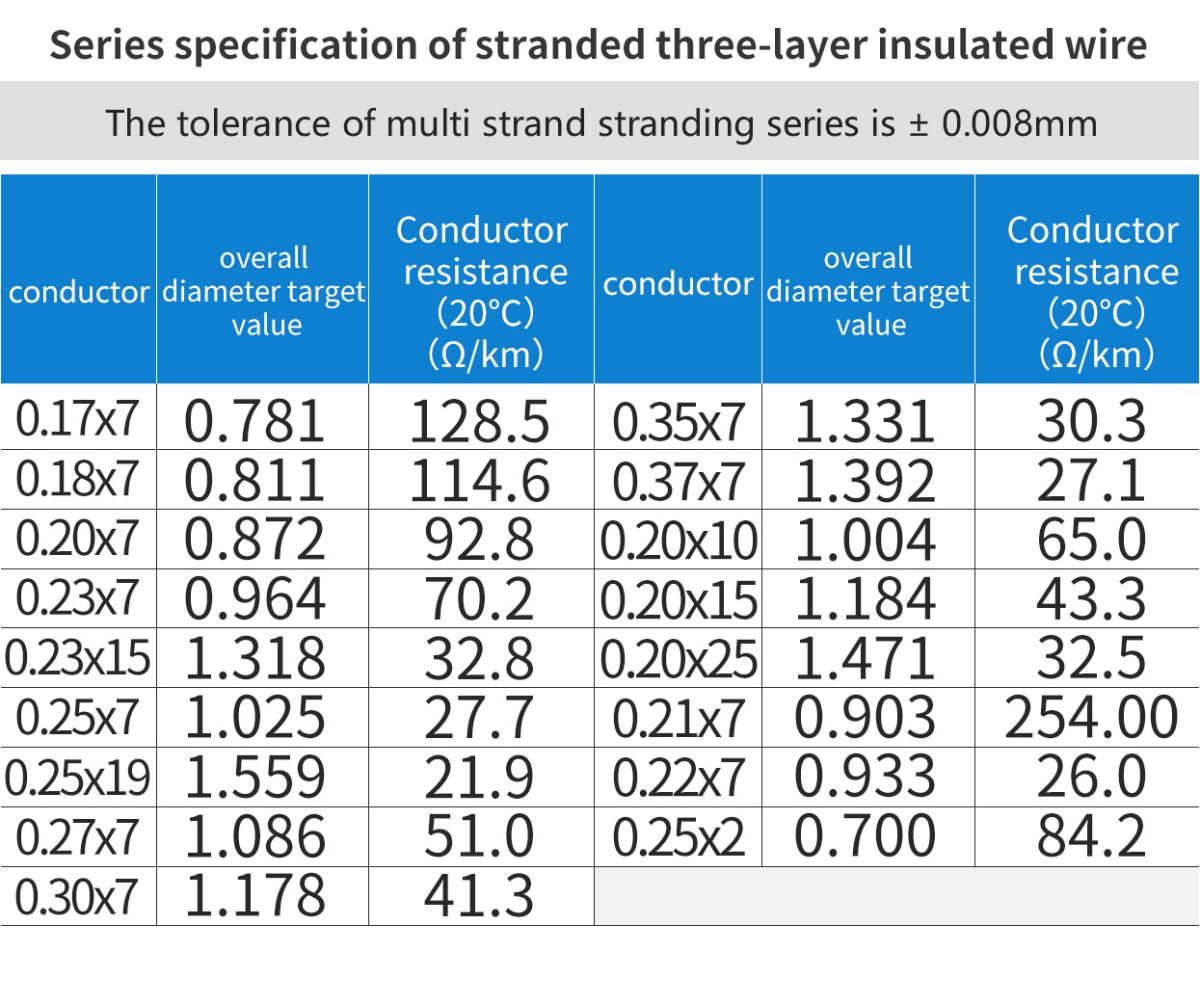

The measurement of the outer diameter of the finished product requires the use of a measuring device with an accuracy of 1/1000mm, such as: a laser outer diameter tester, etc. The measurement of the outer diameter of the finished product adopts the following method: cut off a sample with a length of about 15cm, and place it on a surface perpendicular to the sample. Above, measure the diameter at three points at almost equiangular intervals, and use the average of these measured values to represent the outer diameter of the finished product

The measurement of the outer diameter of the finished product requires the use of a measuring device with an accuracy of 1/1000mm, such as: a laser outer diameter tester, etc. The measurement of the outer diameter of the finished product adopts the following method: cut off a sample with a length of about 15cm, and place it on a surface perpendicular to the sample. Above, measure the diameter at three points at almost equiangular intervals, and use the average of these measured values to represent the outer diameter of the finished product