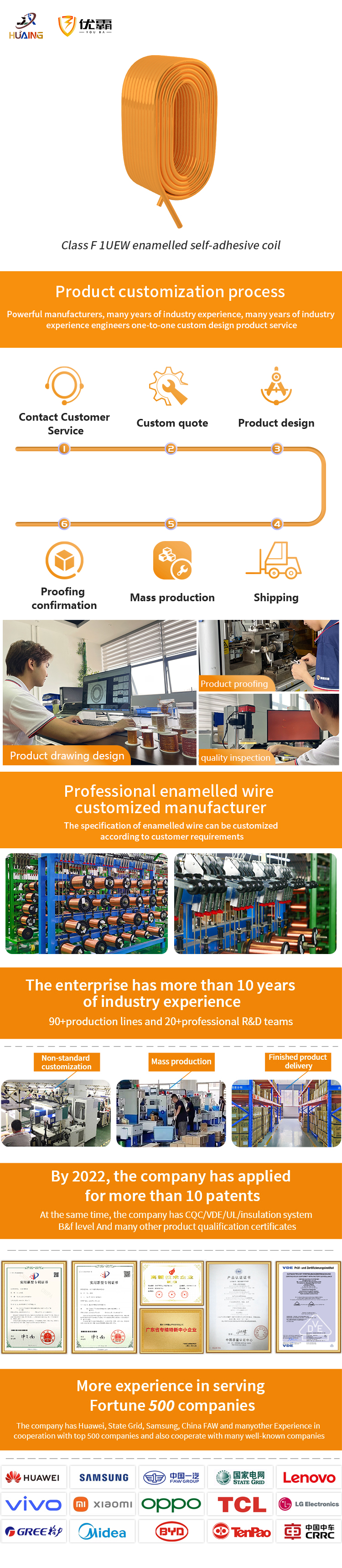

Temperature and pressure resistance to improve work efficiency F-class 1UEW enamelled self-adhesive coil industrial electronic medical

As a special enameled wire, self-adhesive enameled wire is easy to manufacture because of its special processing performance. The wound coil can be bonded and formed after heating or solvent treatment, so it is very popular and widely used in the manufacture of various complex-shaped or frameless electromagnetic coils. The application of self-adhesive enameled wire also brings significant social and economic benefits. It can simplify the coil forming process, improve work efficiency, save energy, improve environmental pollution, and is conducive to industrial production.

Products Details

Featured Products

-

UL Certified 3-Layer Insulated Wire - High Temp & Voltage Resistant | Factory Direct Pricing

-

Solderable insulation, high voltage withstand, super thick paint film, wear-resistant network transformer, polyamide enamelled wire can be customized

-

Yellow three-layer insulated wire high temperature withstand voltage UL certification

-

Single core bare copper wire adapter Power transformer Three layer Teflon self-adhesive coil hot-melt coating can be customized

-

New energy charging pile H-class customizable high-temperature film wrapped coil photovoltaic high-power transformer

-

Green triple insulated wire manufacturer for transformer

-

High mechanical performance, heat resistance, and compression resistance, customizable F-grade gold Teflon self-adhesive coil, new energy for photovoltaic equipment

-

High-Temp Wireless Charger Coils: Factory Direct, Durable & Versatile Models Available

-

Optical storage high temperature resistant twisted square insulated conductor high-power multi-core enamelled wire

-

Network transformer Direct welding polyurethane 180 grade direct welding FIW enamelled wire power transformer can be customized

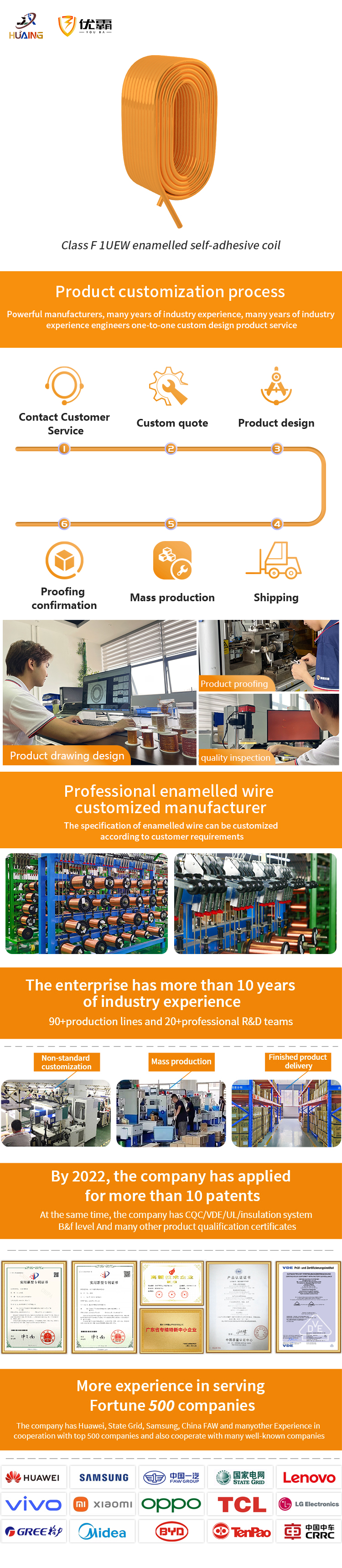

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours